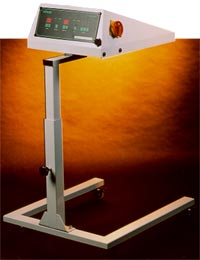

The Flash Cure is a micro-processor controlled unit to rapidly cure plastisol or waterbased inks.

This intermediate drier employs specially developed short wave or intermediate wave quartz halogen lamps for maximum heat control and long life.

It is for use with hand or automatic carousels. A micro processor controls heat intensity and time control.

The heating area is divided into 3 separate zones and the drier can be operated through an interface with an automatic carousel or with a photocell, foot, wobble or micro switch.

Further characteristics:

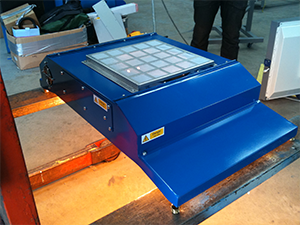

The 5050 flash cure comprise a Short Wave intermediate drier with quartz halogen lamps and a Medium Wave unit with infrared carbon lamps.

The new Medium Wave driers represent the latest technology in flash curing using for the first time specially developed carbon emitters which produce the precise wavelength for fast even curing. The computer designed reflectors ensure even distribution of the air and radiated heat.

The latest micro processor driven controllers which are incorporated in every model give exact control over intensity and time. The combination of the new carbon emitters and these controllers ensure the fastest production rates and coolest cure, and in most cases

eliminate the need for a cool down station.

These Sanco Technology Ltd units will fit with "no tools" in automatic carousels from MHM, Schenk and Hebbecker, but with a stand they can be used in a free (open) station of any other type of carousel.

Application advantages of Medium Wave driers:

Technical Advantages: